Pickup Rings

$248.00

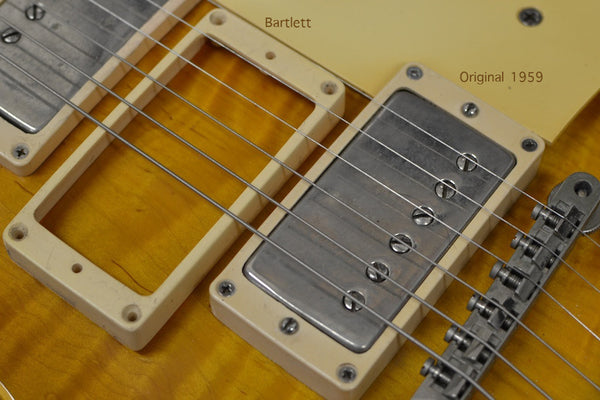

These pickup rings are exact replicas of cream "M-69" pickup rings made in the late 1950's.

Every effort has been made to make these as close to identical as possible.

These smell correct, look correct and feel correct, because they are correct!

The plastic was made by grinding up an original ring and having the plastic analyzed for chemical makeup and consistency. We were able to read the amount of plasticizer present, and calculate how much off gassing had occurred to the original part based on its age. This allowed us to determine the correct amount of plasticizer needed to create an absolutely authentic part.

Colour, texture and opacity were all matched to a set of original cream rings, and compared to many more original sets for verification.

The plastic itself is Cellulose Acetate Butyrate (C.A.B.), and is formulated just as it was in the late 1950's. The plastic off-gases a unique smell - a tell tale sign of C.A.B.

Modern C.A.B often has an 'odor mask' added to remove or mask the unpleasant smell, often with sweet smelling perfumed scents, but that was not what we wanted for an absolutely faithful replica part.

These small pieces of plastic may seem insignificant, but they are the only thing that bridges the gap between the wood of your guitar and the pickups. They need to be right in order to be as faithful to the originals as possible.

These rings will bring your guitar that much closer to being a true replica of a 1950's 'Burst.

The Tooling

The tooling for these rings is faithful down to the very finest details. Even surface texture of the underside is reproduced faithfully.

In the late 1950's the original tooling sustained some damage and was repaired by hand. Our tooling has the same repair so it is identical to the original.

The slightly rounded over edges and bowed short ends are classic signs that these rings are authentic in every detail.

These are the subtleties that set these rings apart from everything else made after the originals.

The original tooling was made long before the advent of CNC technology, so all the hand worked surfaces and old school machining is apparent in the finished part. We have worked very hard to ensure these rings have every detail reproduced, even those little ‘accidents’ that the originals have are present.

The Process

These rings are injection molded properly with no cold joint that could lead to cracking/splitting. You do not need to use hot water to bend these rings.

The original tooling has “gates” that allow the plastic to flow into the mold. These gates need to be placed in the correct spots to avoid having a cold joint in a weak area of the ring.

Properly gating the molds means these can be flexed and bent over the top of your guitar without fear of them ever splitting, or ever having to use hot water. The original rings from the 50’s never split at cold joints, and neither do these.

The neck and bridge ring are both injected into the mold at the same time, and are a ‘matched set’. This way the conditions for each of the two rings is identical. After the parts are injected, the plastic is allowed to cool in the mold to prevent shrinkage and distortion. This process takes time, but it is a requirement to produce absolutely faithful replica parts.

After the plastic cools sufficiently, they are ejected from the mold at just the right moment. This leaves small impressions in the plastic from the ejector pins that press into the slightly soft plastic and leave their mark.

These pins are all placed accurately. Even the texture applied to the ends of the pins is faithfully reproduced, which leaves the same markings on the finished parts as the originals.

Finally - after the part is ejected, they need to be manually separated. This is done by carefully snipping away the ‘flash’ and ‘trim’ this is the plastic the leads to the molds, and cools without being integrated into the finished part. Often this waste plastic, or ‘flash’ is reground and used again in the mold to reduce waste, however, this ‘regrind’ changes the compound after being heated and cooled repeatedly. We do not use any regrind in our rings.

Once the flash is removed, we must manually finish each ring one at a time by grinding down the gate area flush by hand, and finishing the parts cleanup. Finally the rings are aged one at a time individually for the perfect finished product.

Please take a look at the photos below and see for yourself the level of detail these rings have.

Related Items

CNC Shaped Nylon Nut Blanks Exact Vintage

$22.00

These nut blanks are precision CNC machined to fit a 1950's LP. Made from nylon 6/6 and cut slightly oversized. They are more difficult to work than other plastics or...

Holly Veneer

$24.00

Holly veneer for headstock overlays. Slightly thicker than required to accommodate sanding.

Inlays

$75.00

These Inlays are genuine cellulose nitrate, manufactured by Mazzucchelli in the original Italian factory that supplied Gibson in the late 50's they are cut to vintage specs in the correct...